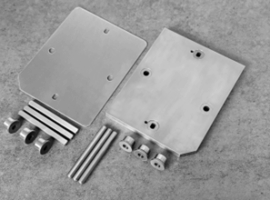

Tooling plate, pin & bushing

Muster anfordernFor over 40 years, TADCO has been making a world of difference in the Printed Circuit Board (PCB) and Plastic Card Lamination industries. Owing to TADCO's unique understanding of the Printed Circuit Board and Plastic Card industry, it has become a leader in the development and manufacture of the highest quality exclusive alloy tooling and accessories. TADCO can achieve the technical requirements your company needs to meet in our ever-evolving technology landscape.

Haben Sie eine Frage? Kontaktieren Sie uns

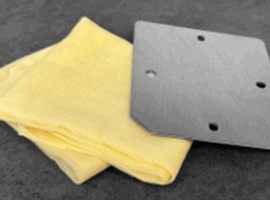

Resin release agent

TADCO release agents form a protective barrier between laminate materials and plates, allowing clean, easy separation while reducing residue buildup during the lamination process.

|

Tuf-Lube 3C / Tuf-Lube 3C HT |

DL-1000 / TL-2000 |

|

|

Max Temp. |

250 °C / 350 °C |

250 °C / 350 °C |

|

Type |

Concentrate Water-Based Release Agent |

Aerosol Spray Release Agent |

|

Key Features |

• Silicone-free compound designed for lamination plates and components • Functions as a release coating, simplifying plate removal and cleaning • When diluted, it provides reliable resin separation from contact surfaces |

• Free from silicone and ozone-depleting substances • Fast-drying propellant enables quick application during the layup process • Forms a protective dry film that supports clean release of epoxy resin from surfaces |

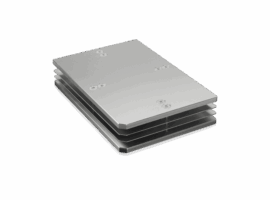

Lamination Tooling and Transport Plate

TADCO Lamination Tooling Plates

Heat Treatment: TADCO utilizes a special proprietary heat treatment method designed to stabilize 4140 steel. This process enables the steel to withstand frequent changes in pressure and temperature with minimal deformation.

Precision Machining: TADCO utilize cutting edge 3 Axis mill equipped with built-in CMM probe. This ensures the accuracy of bushings hole locations within +/- .001”, facilitating multi-layer registration with reliable and consistent result.

TADCO Stainless Steel Separator Plate

Cold rolling includes a work-hardening effect in the material which improves the material’s resistance to deformation, wear, and fatigue.

Leveling involves removing or reducing the coil’s inherent curvature, resulting in a flat and even surface.

Precipitation hardening Stainless steel undergoes an initial quenching process to attain the desired hardness. Subsequently, the quenched alloy is subjected to aging at a comparatively lower temperature, known as the aging temperature. This aging procedure restricts the movement of dislocations, thereby enhancing the material’s strength.

| Press Plates | Separators | |

|---|---|---|

|

Steel type |

4140 alloy |

630 higher nickle content (corrosion resistant) |

|

Hardness |

36/40 Rockwell C |

44/46 Rockwell C |

|

Parallelism |

Within 0.001” TIR |

< 0.03 mm |

|

Flatness |

0.5 mm/m (.005 “/ft) |

< 3 mm/m |

|

Datum to hole location |

±.001” (25 m) |

+/- .005″ |

|

Surface finish |

#32 RMS |

#6 (Rz ≤ 1 m) |

|

Expansion factors (TCE) |

12.1 x 10-6 per °C |

12 x 10-6 per °C |

|

Yield Strength |

136,000 PSI |

1200 MPa |

|

Tensile Strength |

160,000 PSI |

1450 MPa |

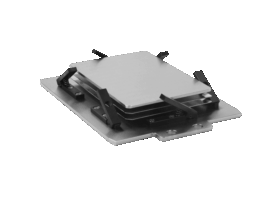

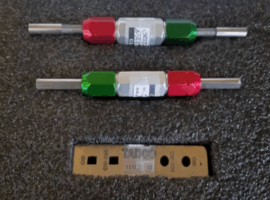

Alignment Pins and Bushings

Tadco’s pins (hardness: 60 to 65 Rockwell C) and bushings (hardness: 54 to 56 Rockwell C) are machined to precise tolerances using very hard special steels and are interchangeable within the industry. Replacements are guaranteed to fit.

Precision Machined Bushings

TADCO’s unique manufacturing process ensures bushings with precisely located holes, enhancing the accuracy of tooling holes on plates and improving PCB layer alignment.

Engineered Tolerances for Superior Fit

Our precision tooling incorporates tightly controlled tolerances for pins, bushings, and plate holes. This design simplifies the lay-up process, enabling easy pin insertion and accurate multilayer lamination registration.

| Slotted | Round | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Bushings |

Inner Ø |

4,76×6,35mm |

3,17mm or 4,76 or 6,35mm |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Height |

6,98 ; 7,11 ; 9,02 or 9,52 mm |

7,11 ; 9,02 mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Pins |

Ø |

4,76×6,35mm |

3,17mm or 4,76 or 6,35mm |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Length |

2,54 ; 3,17 ; 3,81 ; 4,44 cm |

2,54 ; 3,17 ; 3,81 ; 4,44 cm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Other types and sizes are available on request. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Accessoires & Equipment

Tadco offers a complete line of accessories for use in lamination and drill rooms including:

Tacky Cloth:

Tacky Cloth cleans separators by capturing and removing fine particles and debris.

Bushing Brushes (.1875” or .250”):

To remove resin from bushings.

Pin and Bushing Inspection Kit:

To determine quickly and accurately the condition of your pins and bushings.

Bushing Installation Kit

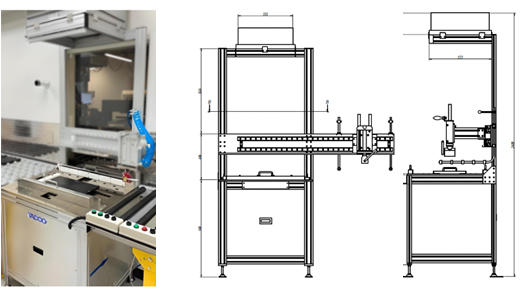

TADCO Pin Advance Lay-up Table with HEPA filtration

Improve registration in the lay-up process

- Eliminate need to stretch layer over lamination pins during lay-up process and registration hole distortion or damage.