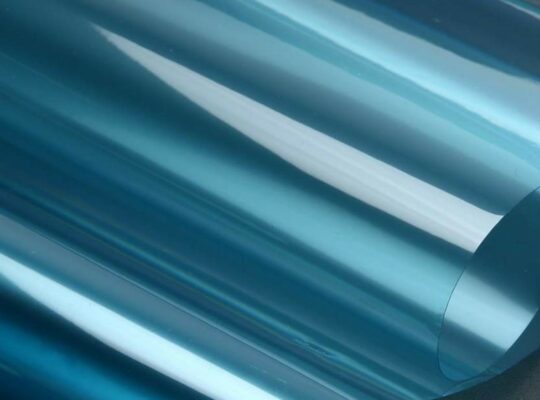

Riston® Dry films

Muster anfordernDuPont™ Riston® dry film photoresist revolutionized the way PCBs were fabricated when invented by DuPont 40 years ago. The original dry film photoresist is the industry standard for high yield, productivity, and ease of use in all imaging applications, including the latest industry demands for finer features, higher quality and lower cost in all types of plating and etching applications as well as LDI exposure.

Haben Sie eine Frage? Kontaktieren Sie uns

Riston® ES 100 series

High productive resist for rapid exposure, development and stripping and fine line innerlayer performance

| Name | Etching environment | Thickness µm | |

|---|---|---|---|

|

ES 102 |

Acid etching |

30 |

|

|

ES 140 |

Acid etching and Cu, Sn plating |

38 |

|

|

ES 150 |

Acid etching and Cu, Sn plating |

50 |

Riston® EM 930 EtchMaster series

High productive resist for rapid exposure, development and stripping and fine line innerlayer performance

Riston® PM 200 Plate Master series

Excellent tenting and plating resist with increased flexibility and productivity

| Name | Etching environment | Thickness µm | |

|---|---|---|---|

|

PM 240 |

Acid etching, Plating |

38 |

|

|

PM 250 |

Acid etching, Plating |

50 |

|

|

PM 275 |

Plating (Cu, Sn, SnPb) |

75 |

Riston® MM 100 MultiMaster series

General purpose resist with strong performance in high pH alkaline etching and aggressive gold plating environment simplifies the manufacturing operation by eliminating the need for different films in your production line

| Name | Etching environment | Thickness µm | |

|---|---|---|---|

|

MM 140 |

High pH alkaline etching and aggressive gold plating |

38 |

|

|

MM 150 |

High pH alkaline etching and aggressive gold plating |

50 |

Riston® MM 700 MultiMaster series

Robust resist with wide developing process window. Suitable for both conventional and LDI exposure (355nm)

Riston® LDI 7000/7200 Laser series

Very high photospeed resists for laser direct imaging

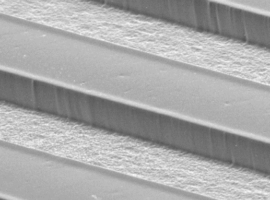

Riston® FX 900 Special series

Designed to produce the new, high resolution innerlayers demanded for the leading edge PCBs. Excellent flow during lamination

| Name | Etching environment | Thickness µm | |

|---|---|---|---|

|

FX 920 |

Acid etch |

20 |

|

|

FX 930 |

Acid and alkaline etch |

30 |

|

|

FX 940 |

Acid etch, Plating Cu, SnPb |

40 |

|

|

FX 950 |

Acid etch, Plating Cu, SnPb |

50 |

Riston® GM 100 Gold Master series

Thick plating film for selective Ni/Au plating and chemical milling

| Name | Etching environment | Thickness µm | |

|---|---|---|---|

|

GM 130 |

Vacuum Lamination, Ni/Au Plating and Chemical Milling |

75 |

|

|

GM 140 |

Vacuum Lamination, Ni/Au Plating and Chemical Milling |

100 |

Riston® FX 250 Special series

Speciality product tough enough to stand up to harsh selective metalization processes, such as electroless nickel immersion gold (ENIG)

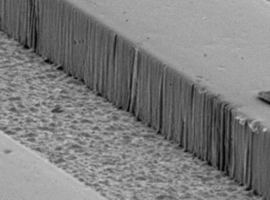

Riston® DI3000 Dry Film Photoresist for Multi-layered Boards

Next Generation T/E and P/E direct imaging photoresist. Excellent tenting, chemical resistance and wind operation window enable higher yield.

Features:

- Superior tenting capability

- Excellent chemical resistance with no ragged line

- Wide operation window by fine line capability

- Capable with i-line & h-line multiple wavelength DI equipment

- Low sludge/foaming for easy maintenance

| Name | Etching environment | Thickness µm | |

|---|---|---|---|

|

DI3030 |

High speed resist, plating Cu, SnPb, Ni/Au, Acid and alkaline etching, chemical milling |

30 |

|

|

DI3038 |

High speed resist, plating Cu, SnPb, Ni/Au, Acid and alkaline etching, chemical milling |

38 |

|

|

DI3050 |

High speed resist, plating Cu, SnPb, Ni/Au, Acid and alkaline etching, chemical milling |

50 |

|

|

DI3062 |

High speed resist, plating Cu, SnPb, Ni/Au, Acid and alkaline etching, chemical milling |

62 |

|

|

DI3075 |

High speed resist, plating Cu, SnPb, Ni/Au, Acid and alkaline etching, chemical milling |

75 |

|

|

DI3099 |

High speed resist, plating Cu, SnPb, Ni/Au, Acid and alkaline etching, chemical milling |

100 |