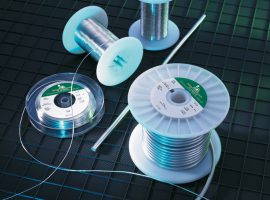

Solder Wires & Fluxes

Request a sampleIndium Corporation manufactures a broad range of solid and flux-cored solder wire. Available in several diameters, several alloys and high to very low flux %. It manufactures as well a broad range of TacFlux™ and flux pens.

Have a question? Get in touch

Flux Cored Wire

| Product name | Cleaning | Halogen | Residues | Class | Alloy compatibility | Description | Datasheet |

|---|---|---|---|---|---|---|---|

|

Core230-RC |

No-clean |

light-colored |

REL1 |

SnPb & SAC |

Fast wetting, Low-Spatter, excellent for robotics soldering. |

||

|

CW-818 |

No-clean |

Halogen-free |

clear |

ROL0 |

SnPb & SAC |

General purpose electronics soldering |

|

|

CW-301 |

Water wash |

ORH1 |

SnPb & SAC |

Excellent cleanability with cold water. |

Liquid flux pens

Indium Corporation’s flux pens utilize a spring-loaded applicator tip to deliver a controlled amount of flux to the work surface. The user friendly pin-point applicator is ideal for touch-up and light assembly work. To apply, simply depress the tip of the flux pen against the work area to start the flow of the applicator tip.

| Product name | Cleaning | Halogen | Residues | Class | Alloy compatibilty | Description | Datasheet |

|---|---|---|---|---|---|---|---|

|

FP-500 |

No-clean |

Halogen-free |

ROL0 |

Sn/Pb & Pb-free |

Passes SIR unactivated. No over-fluxing of surface and no waste. |

||

|

NC-771 |

No-clean |

Benign, non-sticky |

ORL0 |

Sn/Pb & Pb-free |

Backwards compatible with eutectic Sn/Pb. Excellent wetting. Passes SIR unactivated. No over-fluxing of surface and no waste |

||

|

FP-300 |

Water wash |

ORM0 |

No over-fluxing of surface and no waste |

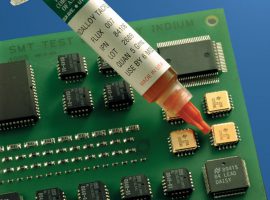

TacFlux™ (viscous fluxes)

Indium Corporation manufactures a complete line of TACFlux® which includes no-clean, water-wash, and RMA-based fluxes. Its many uses include: rework and repair of various electronics assemblies and components, SMT component attach (including BGAs and flip-chips), BGA ball-attach, preform soldering, and virtually any application where a flux is required. Cycle times are not critical as TACFlux® may sit for hours with no reflow degradation.

| Product name | Cleaning | Halogen | Class | Compatible with | Features | Datasheet |

|---|---|---|---|---|---|---|

|

TacFlux™ 020BRC |

No-clean |

Halogen-free |

ROL0 |

NC-SMQ92J, 5.8LS & 8.9HF series |

Passes SIR unheated |

|

|

TacFlux™ 010 |

No-clean |

Halogen-free |

ORL0 |

NC-SMQ75 |

Ultra low post reflow residues. |

|

|

TacFlux™ 089HF |

No-clean |

Halogen-free |

ROL0 |

8.9HF serie |

Excellent soldering and thermal stability. Eliminates HIP. |

|

|

TacFlux™ 012 |

No-clean |

Halogen-free |

ROL0 |

NC-SMQ80 & Indium based alloys |

||

|

TacFlux™ 057 |

No-clean |

Halogen-free |

ROL0 |

5.7LT and Bi based alloys |

low activation Temp for low-melting SnBi & SnBiAg alloys |

|

|

TacFlux™ 025-NP |

Water-wash |

Halogen-free |

ORM0 |

All Indium water-wash solder paste |

Excellent wetting with all common solders and surfaces |

|

|

TacFlux™ 007 |

No-clean |

ROL1 |

NC-SMQ51-SC and AuSn |

leading die-attach flux for the LED industry |