Kingboard FR4 & CEM1

Request a sampleSince its first laminate manufacturing plant in 1988 in Shenzhen, the Kingboard Laminates Group (KL) expanded its production of new CCL, including FR4 and CEM1. Vertically, KL expanded into the production of key upstream component materials, including copper foil, glass yarn, glass fabric and epoxy resin. These developments have placed KL in a competitive position by optimizing economies of scale and achieving cost efficiencies. KL currently operates more than 20 manufacturing plants in China.

Have a question? Get in touch

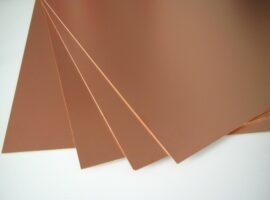

FR4 laminates

Glass Epoxy laminates

KB-5150 is a CEM1 composite material with an inner core of epoxy/paper and outer plies of epoxy/glass. It offers many of the advantages of glass laminates at a price which is closer to that of paper laminates.

KB-5150 is available either yellow or white with CTIs ranging from 175 to 600.

Paper Laminates

Kingboard’s KB-2150GC sets the standard for high end paper-base laminate. It is a high strength paper/phenolic grade suitable for warm punching, and combines flame retardancy with the electrical/mechanical properties of a NEMA XX grade.

Black FR4

Black coloured FR4 material

Dimensions: Sheets or cut to size panels

Unclad FR4/EP105/CEM-1

Unclad FR4, EP105, CEM-1 are rigid material providing a good mechanical stability to your test fixure.

Dimensions: Cut to size panels